LFV TECHNOLOGY

LFV TECHNOLOGY

The Swiss Machining World Will Never be the Same with this Revolutionary Chip Control Technology!

What is Low Frequency Vibration Cutting?

The servo axes are vibrated in the axial direction and cutting is performed while synchronizing this vibration with the rotation of the spindle. Because “air-cutting” times are provided during cutting, it is characterized by intermittent expulsion of chips. Programmable chip control!

This widely applicable cutting technology – able to handle a broad range of machining shapes and materials – is ideal for cutting difficult-to-cut materials like inconel, stainless steel, copper, and plastics, among others. It is state-of-the-art and reduces risks associated with these materials, such as nesting of chips and built-up edges. Improved throughput!

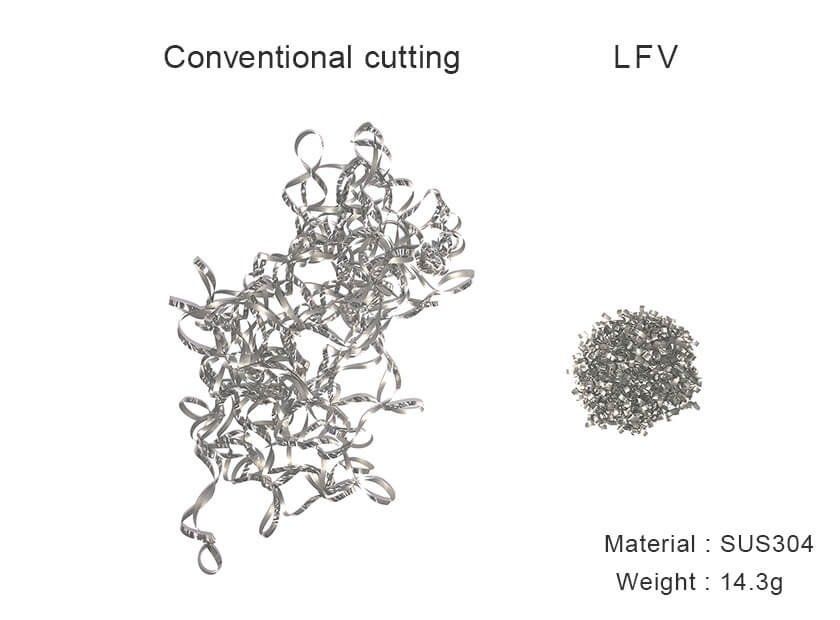

Citizen LFV Cutting Technology – Reduced Chip Sizes

- Programmable chip control, breaking chips into very fine pieces as you cut

- Eliminate chip nesting and entangling with the material or tool.

- Dramatically reduce the need for high pressure coolant

- Ideal for difficult to machine materials and malleable materials with hard to control chips.

- Reduced pecking and small chip size tremendously advantageous for drilling.

- Substantially increase your throughput with less operator intervention